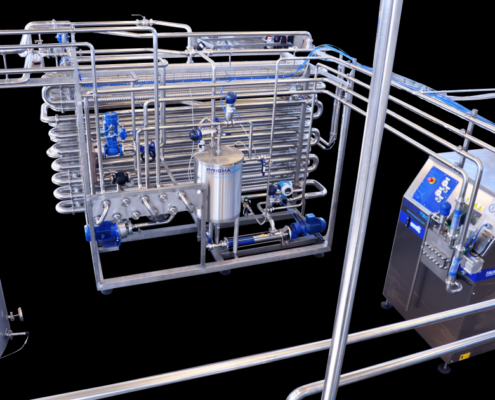

WATER TREATMENT PLANTS (WTP)

In the beverage industry, water is the primary resource and the main ingredient in every preparation. Water is also used for the operation of the machinery itself as a heating or cooling liquid, for the supply of auxiliary equipment, for washing and sanitising plant processes as well as for more common utility uses.

For water to be considered fit for human consumption, it is necessary to ensure its wholesomeness through compliance with various national and international safety parameters. Its physical-chemical-microbiological composition determines the drinking water treatments required, as it is essential that the water be free of bacteria, contaminants and harmful particles. Furthermore, depending on the use and the product to be prepared, the organoleptic properties of the water must also be respected, so as to always guarantee a safe and quality product.

In addition, different areas on the planet require targeted treatments for that area depending on local nutritional needs, which are in turn influenced by diet and climate.

The main steps comprising water treatment are:

- Raw water extraction and storage: raw water is extracted from its source and stored in dedicated tanks.

- Flocculation and clarification: particles and impurities are separated from the pre-treated water.

- Filtration, ultrafiltration and purification (FLUI-TECH): Clarified water is filtered through sediment filters such as sand filters, activated carbon filters (ACF), dual media filters and cartridge filters to remove the smallest impurities still present, to reduce residual mineral salts and substances that can alter the smell and taste of water.

- Disinfection and chlorination (PURI-TECH): filtered water undergoes a disinfection treatment with the addition of chlorine or other chemicals, as appropriate, to kill the bacteria and other pathogenic microorganisms present.

- Reverse osmosis (OSMO-TECH): disinfected water is demineralised and deionised by passing at high pressure through a semi-permeable reverse osmosis membrane that blocks most of the remaining undesirable contaminants such as dissolved salts, bacteria and pathogens.

- Final disinfection (PURI-TECH): water that has undergone reverse osmosis (RO) treatment is now called ‘permeate’ and, to ensure a safe, quality end product, the water can be subjected to additional disinfection treatments using ultraviolet (UV disinfection) or ozone to deactivate pathogenic microorganisms without altering the water taste, colour and odour.

Remineralisation (REMIN-TECH): treated water is safe and free of harmful substances, but sometimes certain treatments it has previously undergone can also remove beneficial minerals. For this reason, a remineralisation process may be necessary in which essential minerals are added to restore or improve the mineral composition and chemical balance, ensuring that it contains an adequate amount of minerals for better quality, taste or conductivity. This step is very important and can be customised to suit the characteristics of the treated water, the local nutritional requirements, or the next processes in the chain.

Treated water storage: treated water is ready to be used directly or collected in storage tanks.

SUSTAINABILITY AND OUR COMMITMENT TO THE PLANET

We put environmental protection and health safeguarding at the centre of our goals. In particular, we deal with water purification, recovery and reuse of secondary water resources, such as industrial wastewater. Thanks to our experience and advanced technology, we can provide companies with highly efficient water treatment systems that reduce the environmental impact of production activities and manage water resources in a more sustainable and environmentally-friendly way.