OSMO-TECH REVERSE OSMOSIS FOR WATER (RO)

REVERSE OSMOSIS WATER PURIFICATION PLANT (RO)

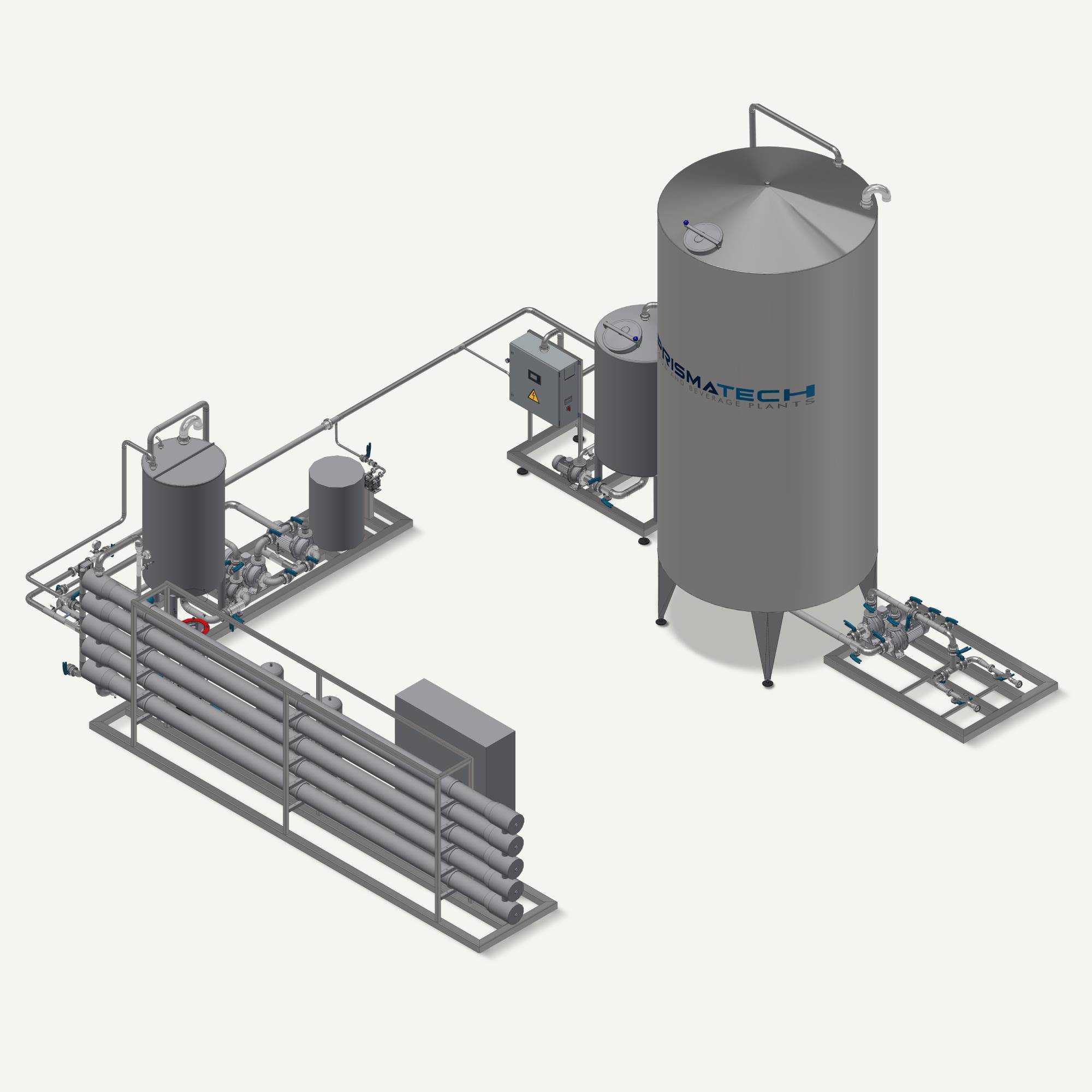

Reverse Osmosis is an essential water purification process in industrial water treatment to remove impurities, dissolved salts and other contaminating water particles (pathogens, bacteria). However, Reverse Osmosis is not sufficient to remove bacteria on its own but must be integrated with one or more disinfection modules within the water treatment plant to ensure bacterial inactivation.

Our OSMO-TECH purification system is suitable for various industrial applications, where production water free of minerals and ions is required, such as food and beverage, pharmaceutical and chemical industries.

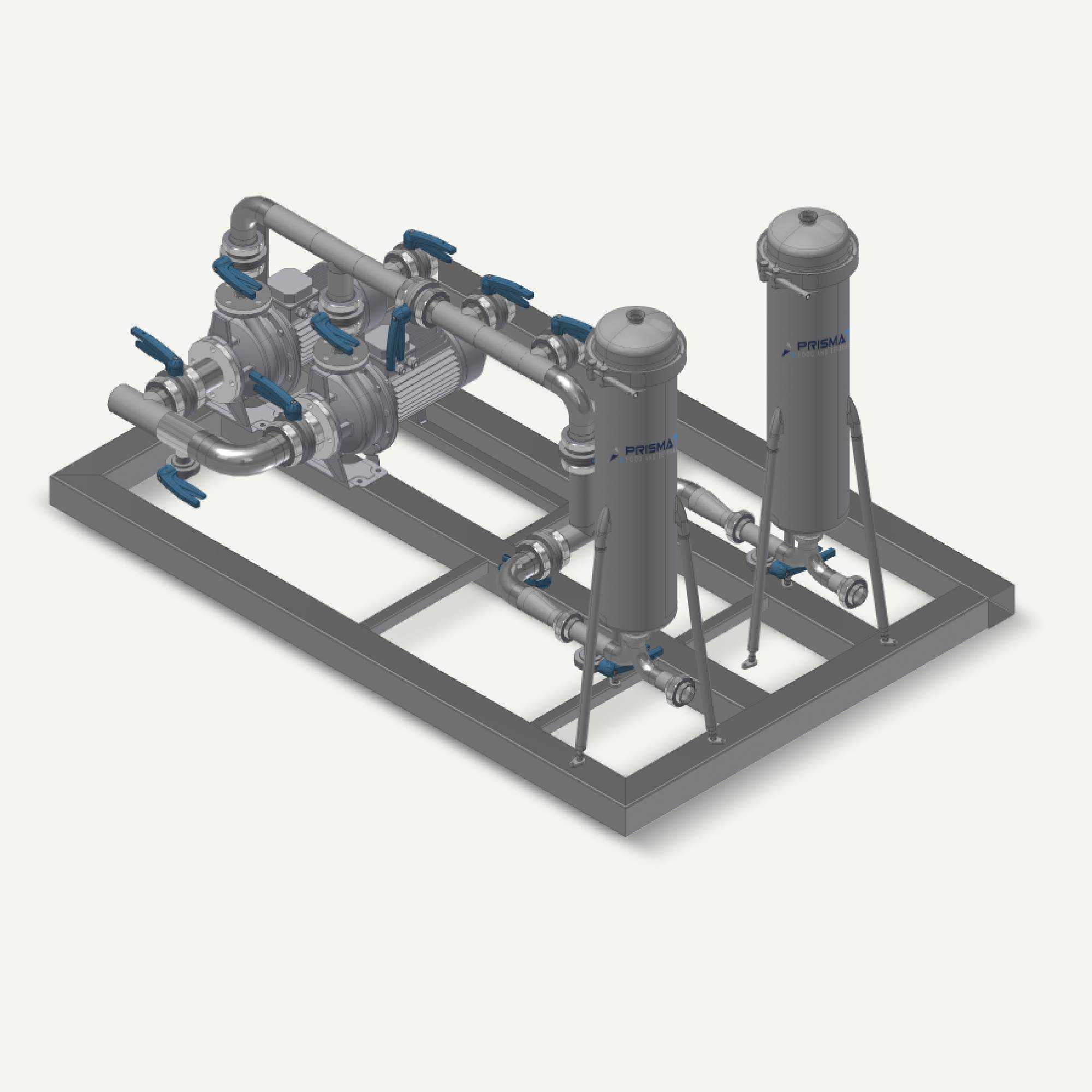

DECALCIFYING PRE-TREATMENT: To prevent fouling of the reverse osmosis (RO) system, filtration and ultrafiltration stages are necessary, as well as the use of chemical agents such as antiscalants and other fouling agents.

Filtration systems used for initial water treatment can be dual-media (DMF) or multi-media (MMF) filters consisting of sand filters, activated carbon filters (ACF) or others, which are combined with cartridge filters for more effective filtration.

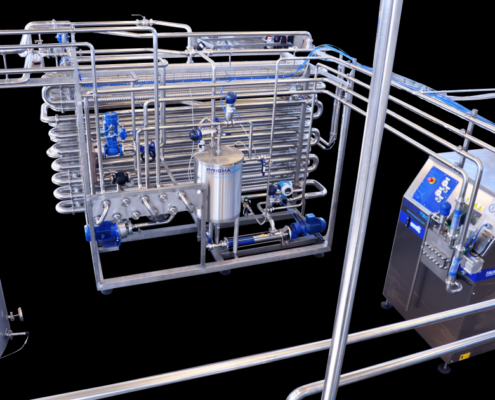

REVERSE OSMOSIS PROCESS: Water is then demineralised and deionised by passing at high pressure through a semi-permeable reverse osmosis membrane, which allows water molecules to migrate, while trapping salts and other impurities.

WASTE CONCENTRATE: Impurities and salts rejected by the membrane are known as ‘concentrate’ or ‘waste’ as this residue is discarded.

PERMEATE: The ‘good’ water allowed to flow from the membrane is called ‘permeate’ or product water.

As with any water treatment line, it is important to start with a water analysis and identify the desired use, as drinking water treatments vary depending on the use and the product to be prepared.

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed for high performance and maximum reliability, our PRISMATECH reverse osmosis systems meet all space and process requirements, always ensuring great energy savings.

In every industrial process for beverage production and water treatment, we ensure energy efficiency, minimisation of waste and preservation of beverage characteristics for a high-quality product.

- NATURAL MINERAL WATER

- SPARKLING MINERAL WATER

- FLAVOURED WATER

- COLLAGEN WATER

- FUNCTIONAL WATER

- DRINKS

- BEAUTY PRODUCTS

- CLEANING PRODUCTS

- COLD FILLING

- ULTRACLEAN FILLING

- ASEPTIC FILLING

- BRICK CARTON FILLING

- PET FILLING

- GLASS FILLING

- CAN FILLING

- 5 MC/H

- 120 MC/H

- MODULAR

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON

- ADJUSTABLE FEET

- CUSTOMISED

- AUTOMATIC

- SEMI-AUTOMATIC

- MANUAL

- FLUID VELOCITY CONTROL

- PRODUCT QUANTITY CONTROL

- CONDUCTIVITY CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE, SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- SINGLE STAGE

- DOUBLE STAGE

- SINGLE PASSAGE

- DOUBLE PASSAGE

- INTEGRATED

- CIP

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0