REMIN-TECH WATER REMINERALISATION

WATER REMINERALISATION PLANT

Remineralisation is an essential step in the water treatment process, especially in systems involving reverse osmosis, as this technology tends to remove not only impurities and contaminants, but also essential minerals from water.

Water remineralisation is a process involving the addition of essential minerals to drinking water in order to restore or improve the mineral content to enhance its quality and make it suitable for human consumption.

This mineral replenishment process is of particular importance in areas such as drinking water treatment, where it is crucial to provide end users with safe and nutritious water. The selection of minerals to be added to water may vary according to specific local nutritional needs, the chemical characteristics of the water to be treated, such as the pH of the water, and consumer preferences.

Furthermore, water remineralisation may be required in certain processes in beverage production lines, when it is necessary to achieve a particular water conductivity. There are two main options for remineralising osmosis water or previously filtered water:

- Reverse osmosis plant bypass: This option involves the creation of a bypass within the reverse osmosis unit, through which a small amount of minerals naturally present in the water can be reintroduced into the treated water. This resulting water can be used as bottled mineral water or as a base water for the preparation of drinks. This method exploits the minerals present in the infeed water to achieve the desired result.

- Customised remineralisation process: Alternatively, a more precise and targeted remineralisation process can be adopted. This process involves adding precise and specific amounts of minerals to the treated water to create a mineral water tailored to the specific needs of the production process. This option offers complete control over the mineral composition of the water, resulting in a final product with exact characteristics.

Water treatment is a specialised process that requires a detailed analysis of the initial water to fully understand the chemical composition and impurities present. This process is crucial in identifying specific water treatment needs and establishing the desired use objectives, as water treatment varies depending on the use and the product to be prepared.

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

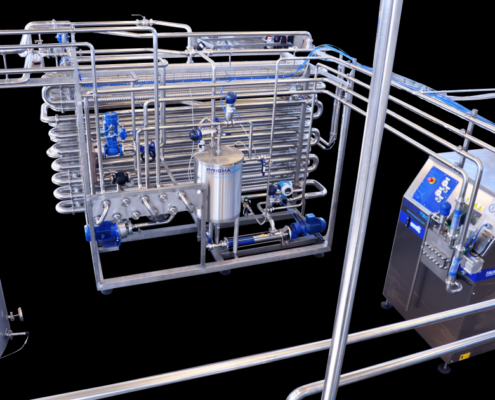

Designed to deliver high performance and maximum reliability, REMIN-TECH PRISMATECH systems meet all security requirements.

In every industrial beverage and water treatment process, we ensure energy efficiency, minimisation of waste and preservation of beverage characteristics for a high-quality product.

- NATURAL MINERAL WATER

- SPARKLING MINERAL WATER

- FLAVOURED WATER

- COLLAGEN WATER

- FUNCTIONAL WATER

- DRINKS

- BEAUTY PRODUCTS

- CLEANING PRODUCTS

- COLD FILLING

- ULTRACLEAN FILLING

- ASEPTIC FILLING

- BRICK CARTON FILLING

- PET FILLING

- GLASS FILLING

- CAN FILLING

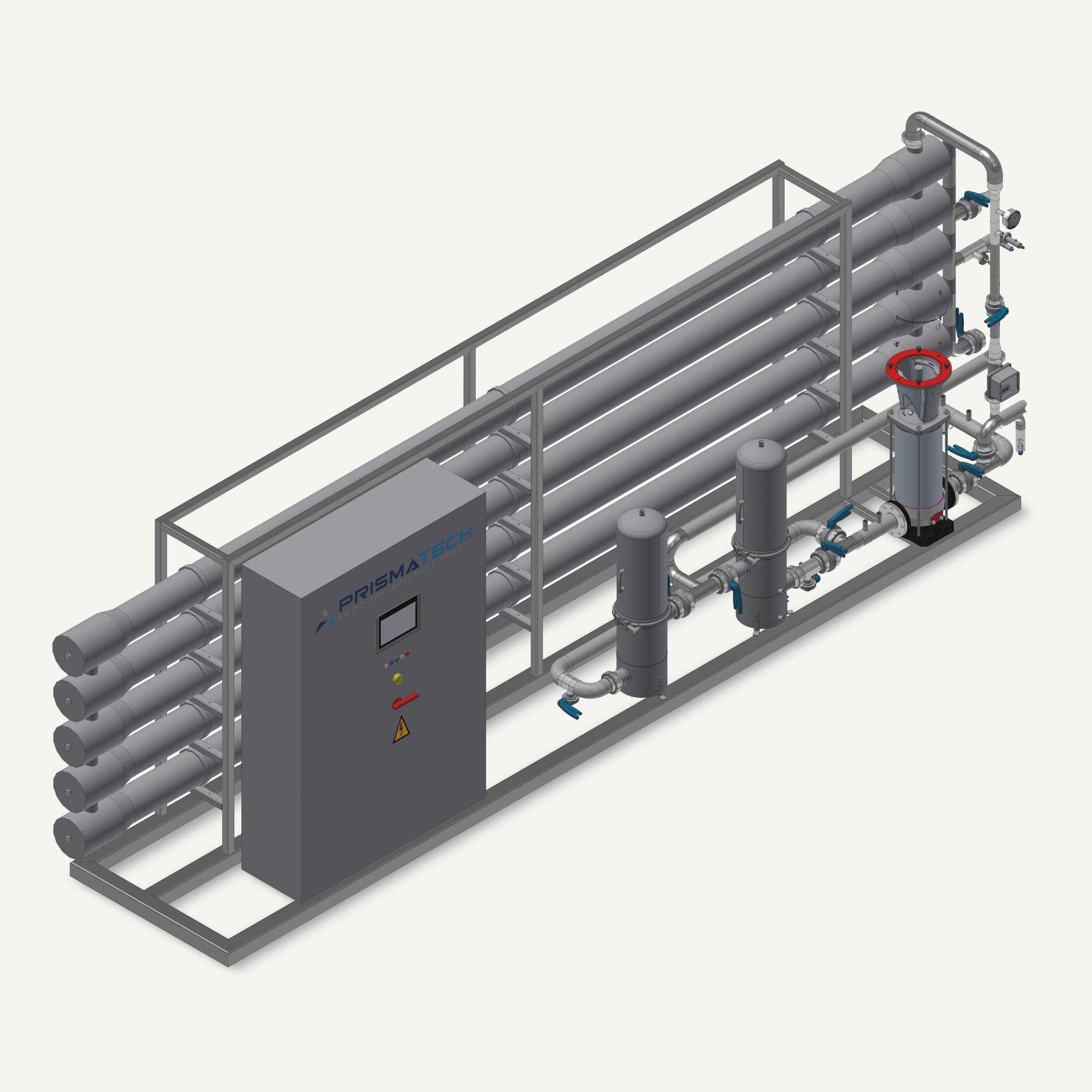

- 5 MC/H

- 120 MC/H

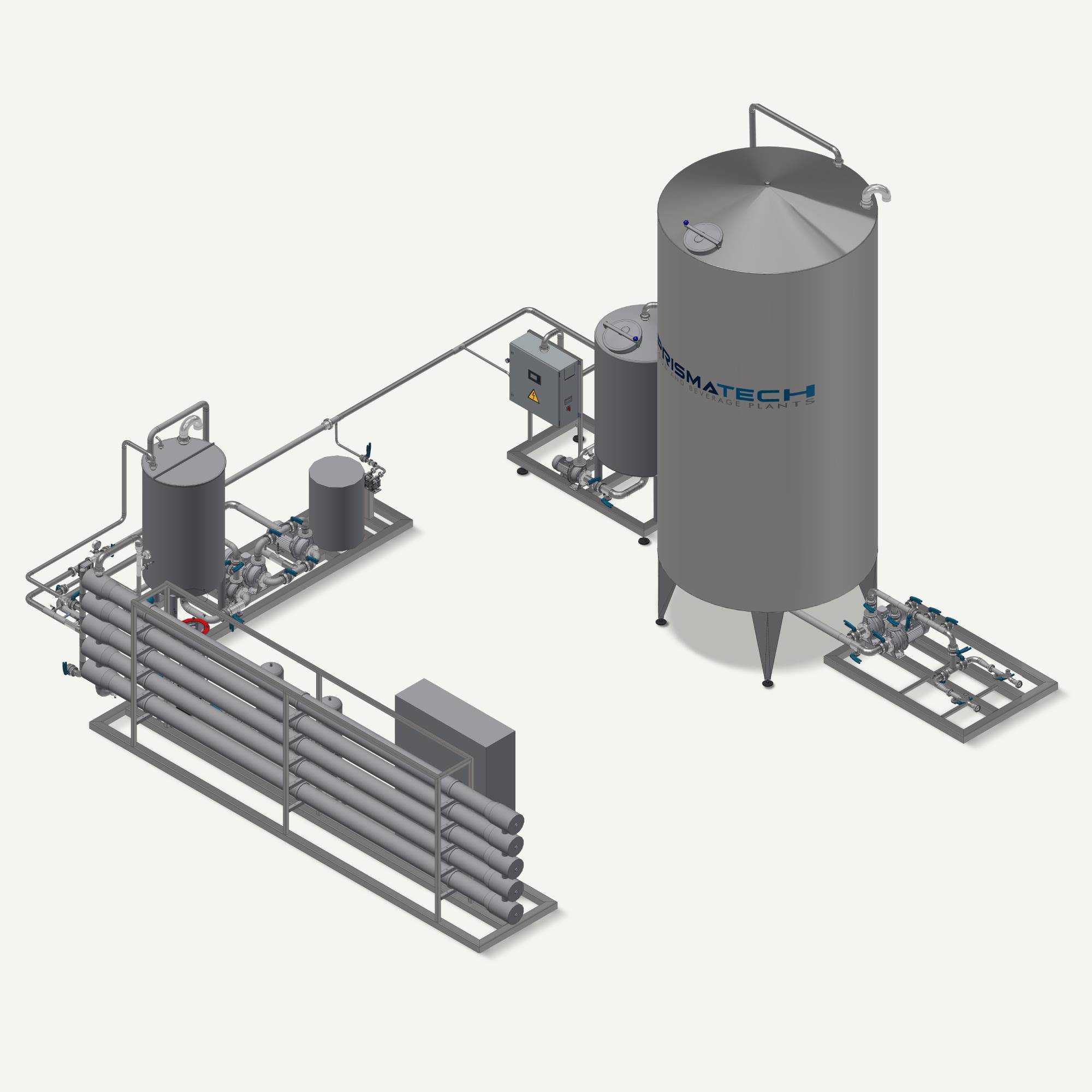

- MODULAR

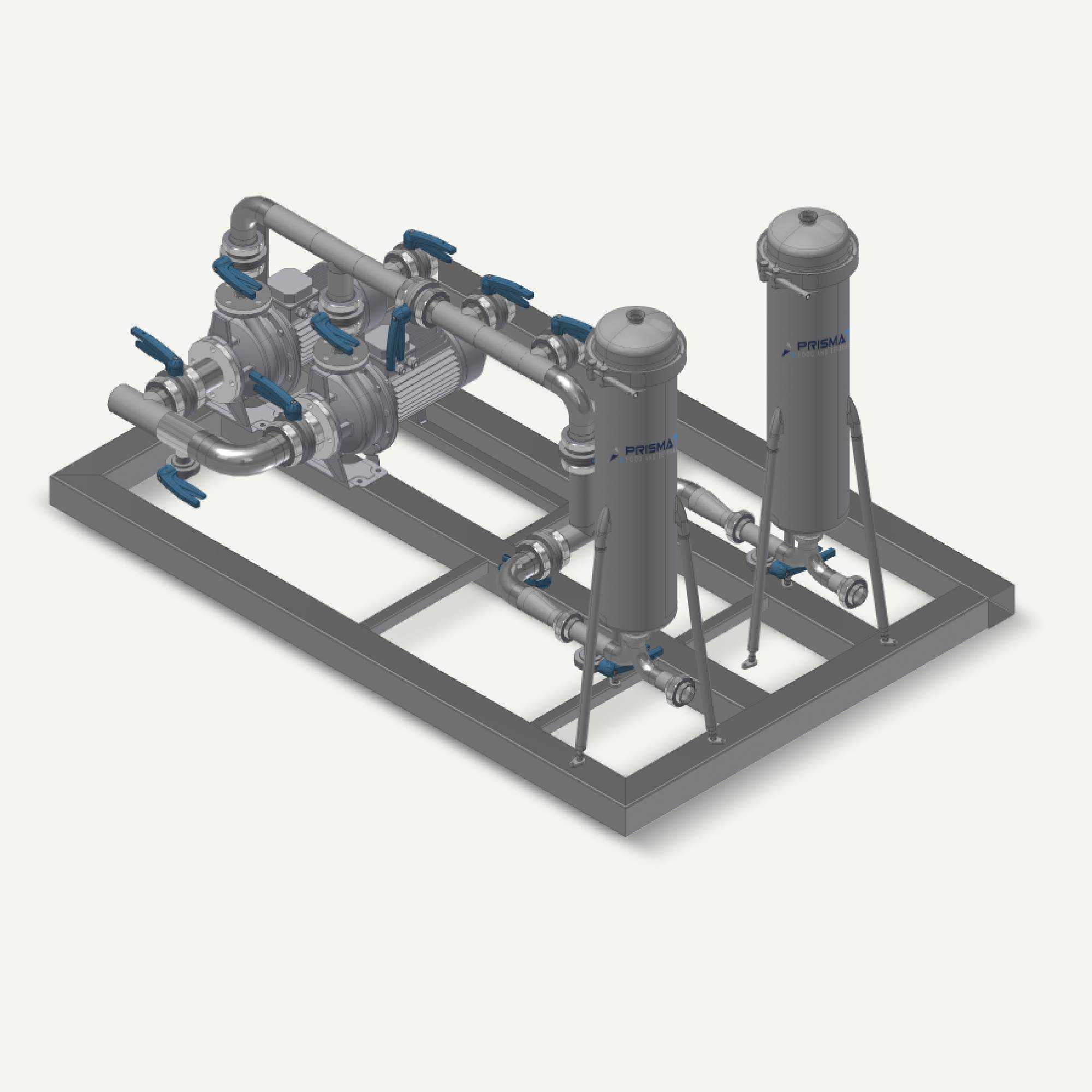

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON ADJUSTABLE FEET

- CUSTOMISED

- AUTOMATIC

- SEMI-AUTOMATIC

- MANUAL

- FLUID VELOCITY CONTROL

- PRODUCT QUANTITY CONTROL

- CONDUCTIVITY CONTROL

- DOSAGE CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- BYPASS OSMOSIS

- MINERAL DOSING

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0