SANI-TECH CLEAN-IN-PLACE (CIP)

CLEAN-IN-PLACE (CIP) WASHING SYSTEM

The cleaning and sanitising of plants are indispensable for maintaining the efficiency of production processes and product quality.

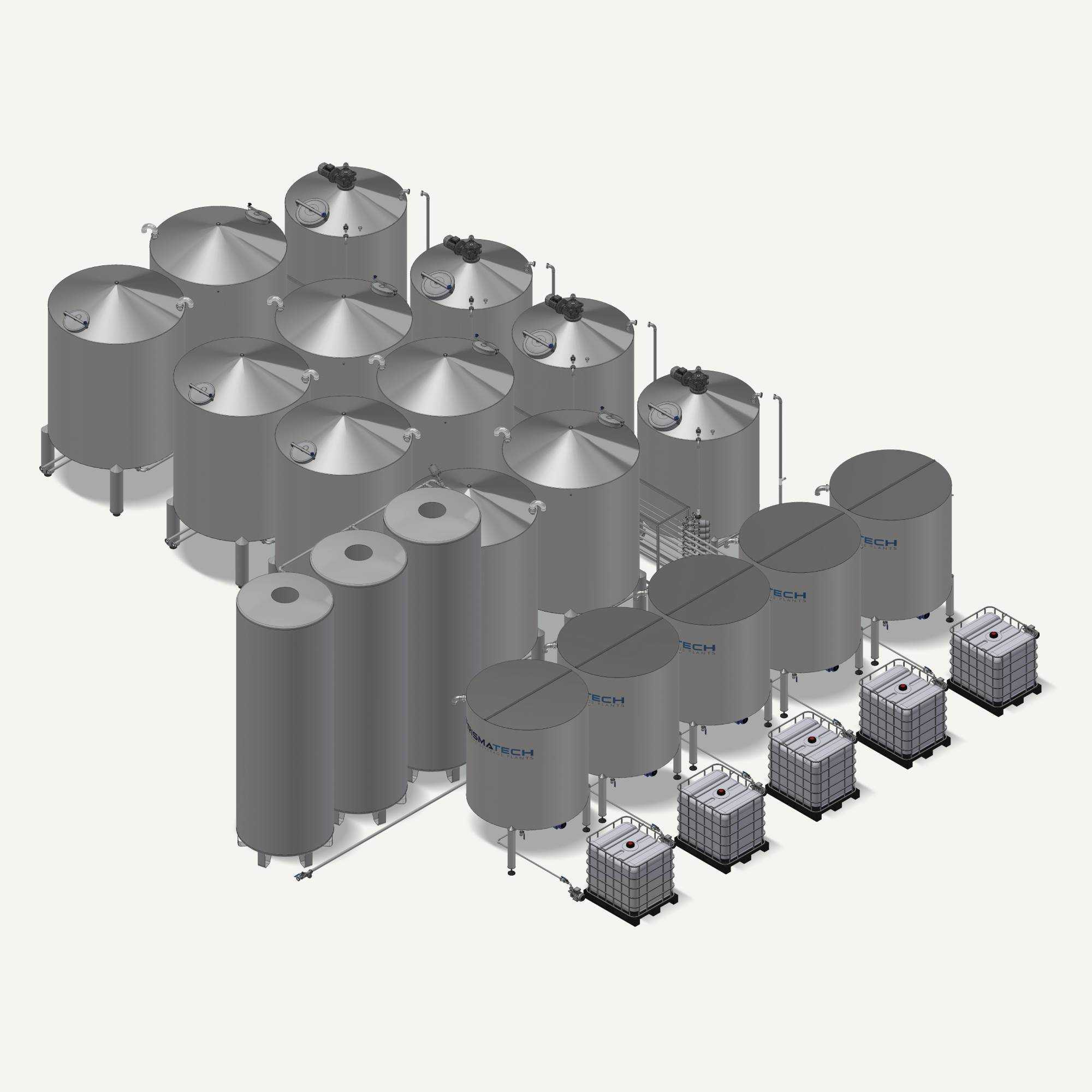

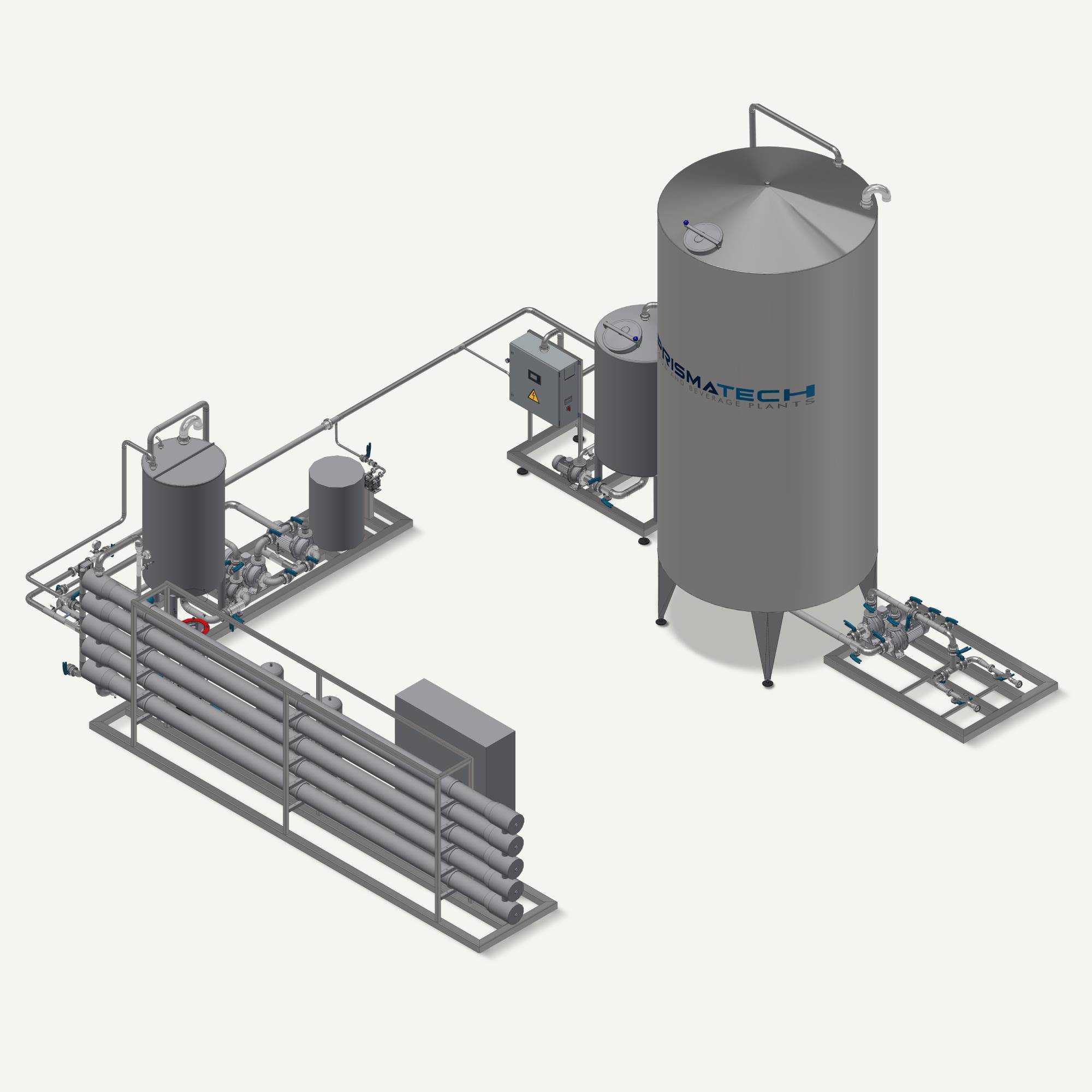

Clean-in-place (CIP) systems are systems mainly used in the food and beverage, pharmaceutical and chemical industries for the automatic cleaning and disinfection of production facilities, such as tanks, pipes, valves and other equipment, without the need to dismantle them manually. They fulfil the growing need for high standards of hygiene and cleanliness while ensuring efficiency and reducing downtime.

Thanks to continuous research into innovation and attention to the needs of the industry, PRISMATECH’s CIP washing systems are constantly being optimised and improved to offer manufacturers high-performance solutions and make their processes more efficient, contributing to more sustainable production.

Advantages of PRISMATECH’s CIP systems:

- Customisation

All PRISMATECH machines are designed for Cleaning-In-Place washing and each CIP system is fully customisable depending on the product to be removed and the flow rates required.

- Product quality assurance

PRISMATECH’s CIP systems are designed to eliminate contaminants or bacteria responsible for compromising quality, ensuring the excellence of the final product.

- Production and energy efficiency

PRISMATECH’s CIP systems increase the efficiency of beverage processing operations. Automated cleaning and sanitising results in significant savings in time and labour costs as well as reducing the risk of human error.

- Water neutralisation

Wastewater neutralisation by CIP plants refers to the process of treating wastewater to dispose of it in accordance with local and environmental regulations. Wastewater generated during the sanitisation of machinery may contain residues of cleaning chemicals, bacteria, impurities and organic substances, making it polluting and harmful to the environment if discharged without treatment.

- Cost Reduction

PRISMATECH’s CIP systems help reduce costs associated with manual cleaning and downtime for equipment maintenance. Our CIPs also ensure constant equipment maintenance by reducing the risk of breakdowns and costly repairs. Washing agent recovery, heating system optimisation and water reuse in PRISMATECH’s industrial washing systems also lead to further savings in operating costs.

AUTOMATION, DURABILITY AND SUSTAINABILITY

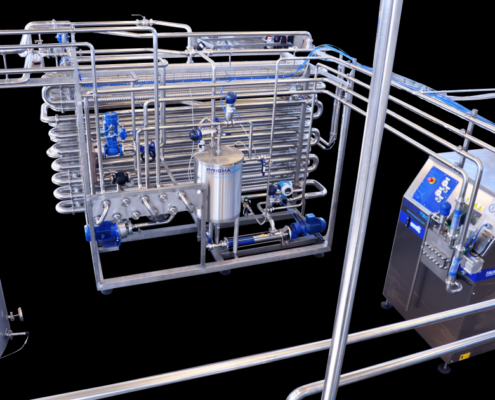

With a wealth of experience, our engineers can advise and help you in the most suitable configuration for your production plant. PRISMATECH’s constant investment in R&D allows us to offer various automation options and state-of-the-art solutions that offer great energy and water savings.

PRISMATECH machines are made of resilient materials with high quality components, offering the highest Made-In-Italy standards.

FLEXIBILITY AND INTEGRATION

The washing systems offered by PRISMATECH easily integrate with any process line in the industrial supply chains of multiple industries, responding to their specific needs by providing tailor-made solutions that improve and optimise production.

PRISMATECH also offers a range of services including the overhaul and reconditioning of existing production facilities and their modernisation.

- AISI 304

- AISI 316L

- HOT WATER

- COLD WATER

- CAUSTIC SODA

- ACID

- DISINFECTANT

- WASHING PRODUCTION LINES

- BEVERAGE INDUSTRY

- FOOD INDUSTRY

- CHEMICAL INDUSTRY

- NUTRACEUTICAL INDUSTRY

- PHARMACEUTICAL INDUSTRY

- 500 L/H

- 100,000 L/H

- MODULAR

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON ADJUSTABLE FEET

- TROLLEY-MOUNTED

- CUSTOMISED

- AUTOMATIC

- SEMI-AUTOMATIC

- MANUAL

- MULTILOOP (MULTIPLE SIMULTANEOUS LINES)

- STEAM

- ELECTRICAL

- TEMPERATURE CONTROL

- CONDUCTIVITY CONTROL

- PRODUCT QUANTITY CONTROL

- PRODUCTION TIME CONTROL

- QUALITY CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- TANK INSULATION

- MAGNETIC FLOW METER ON RETURN

- CONDUCTIVITY METER

- AUTOMATIC DISTRIBUTION WITH MIX PROOF VALVES

- BOILER

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0