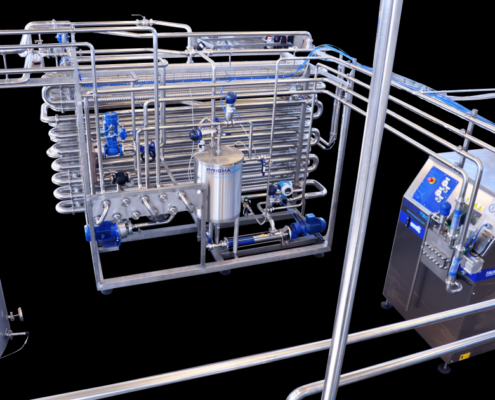

A-LINE WATER LINE

WATER PRODUCTION LINE AND WATER TREATMENT PLANTS (WTP)

Our water lines take the form of state-of-the-art, custom-designed, modular solutions, both for the preparation of liquid cosmetic skin care products such as make-up remover and toner and for the production of consumer water: natural water, sparkling water, flavoured water, functional water, collagen water and beauty water.

To obtain a quality product, it is important to start by treating the source water, ensuring it is healthy and removing any contaminants and harmful substances with our water treatment plants. Depending on the source and use, specific treatments may be required to make the water drinkable or suitable for use in certain sectors.

CUSTOMISED CONFIGURATION

Customised according to your needs and the product to be processed, A-LINE | Water Line configurations can include:

- FLUI-TECH | Water filtration: impurity filtration with sediment filters

- OSMO-TECH | Reverse osmosis: water demineralisation and deionisation

- REMIN-TECH | Remineralisation of water: mineral replenishment system

- PURI-TECH | Water disinfection: chlorine and UV disinfection

- CARBO-TECH | Carbonator: water carbonation system

- OXY-TECH | Deaerator: water deaeration system

- DOSI-TECH | Aroma dosing: flavoured water preparation with inline dosing

- S-LINE | Syrup room: flavoured water preparation

- THERMO-TECH | Pasteuriser: heat treatment for aromatised water

- PRISMACONTROL | Automation systems: Mix-proof double seat valves for product distribution on multiple lines

- SANI-TECH | Clean-In-Place CIP: plant cleaning and sanitising

Water lines can be combined or integrated with our other process lines:

D-LINE | Drinks Line

S-LINE | Syrup Room

F-Line | Food Line

X-LINE | Non-food line

FLEXIBILITY, EFFICIENCY AND QUALITY

Our water lines are made of durable materials with high quality components to guarantee the high standards of ‘Made in Italy’. Our machines are suitable for a wide range of packaging solutions (PET, glass, cans, …), are equipped with various automation options and control systems, and integrate easily into any bottling line. Our plants are designed and optimised to offer great energy and water savings.

- AISI 304

- AISI 316L

- PVC

- GALVANIZED CARBON STEEL

- PROCESS WATER

- MINERAL WATER

- NATURAL WATER

- SPARKLING WATER

- FLAVOURED WATER

- FUNCTIONAL WATER

- COLD FILLING

- ULTRACLEAN FILLING

- ASEPTIC FILLING

- BRICK CARTON FILLING

- PET FILLING

- GLASS FILLING

- CAN FILLING

- 5 MC/H

- 120 MC/H

- MODULAR

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON ADJUSTABLE FEET

- CUSTOMISED

- AUTOMATIC

- SEMI-AUTOMATIC

- MANUAL

- UPGRADE OR RENEWAL

- TEMPERATURE CONTROL

- FLUID VELOCITY CONTROL

- PRODUCT QUANTITY CONTROL

- PRODUCTION TIME CONTROL

- QUALITY CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- LOAD CELLS

- SCREW ELEVATOR

- TANK INSULATION

- MASS FLOW METER

- AUTOMATIC DISTRIBUTION WITH MIX PROOF VALVES

- CHILLER

- BOILER

- COOLING TOWER

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0

- WELL WATER

- RIVER WATER

- CITY WATER

- WASTE WATER

- REVERSE OSMOSIS

- WATER FILTRATION

- WATER REMINERALISATION

- DISINFECTION