PURI-TECH WATER DISINFECTION

WATER DISINFECTION SYSTEM

Water disinfection is recommended at the end of any water treatment line to avoid contamination as it aims to kill or inactivate pathogenic microorganisms such as bacteria, viruses and other harmful agents.

The choice of disinfectant to be used depends on the specific situation, water characteristics and safety standards. Disinfection is important because it prevents the spread of water-borne diseases, protecting human health. It is a fundamental step that helps ensure access to clean and safe water sources for the population.

Water disinfection can be achieved through different methods, each of which has specific advantages depending on the requirements of the treatment process. Below are the three commonly used disinfection methods:

- Chlorine disinfection: Chlorination is a crucial step in disinfecting water from wells or other sources, before it undergoes further treatment, such as reverse osmosis (RO). Chlorine is used to eliminate pathogenic microorganisms in the water. Subsequently, residual chlorine should be removed through the use of an active carbon filter, such as those offered by FLUI-TECH (link). This procedure helps to ensure that the water is safe for subsequent use.

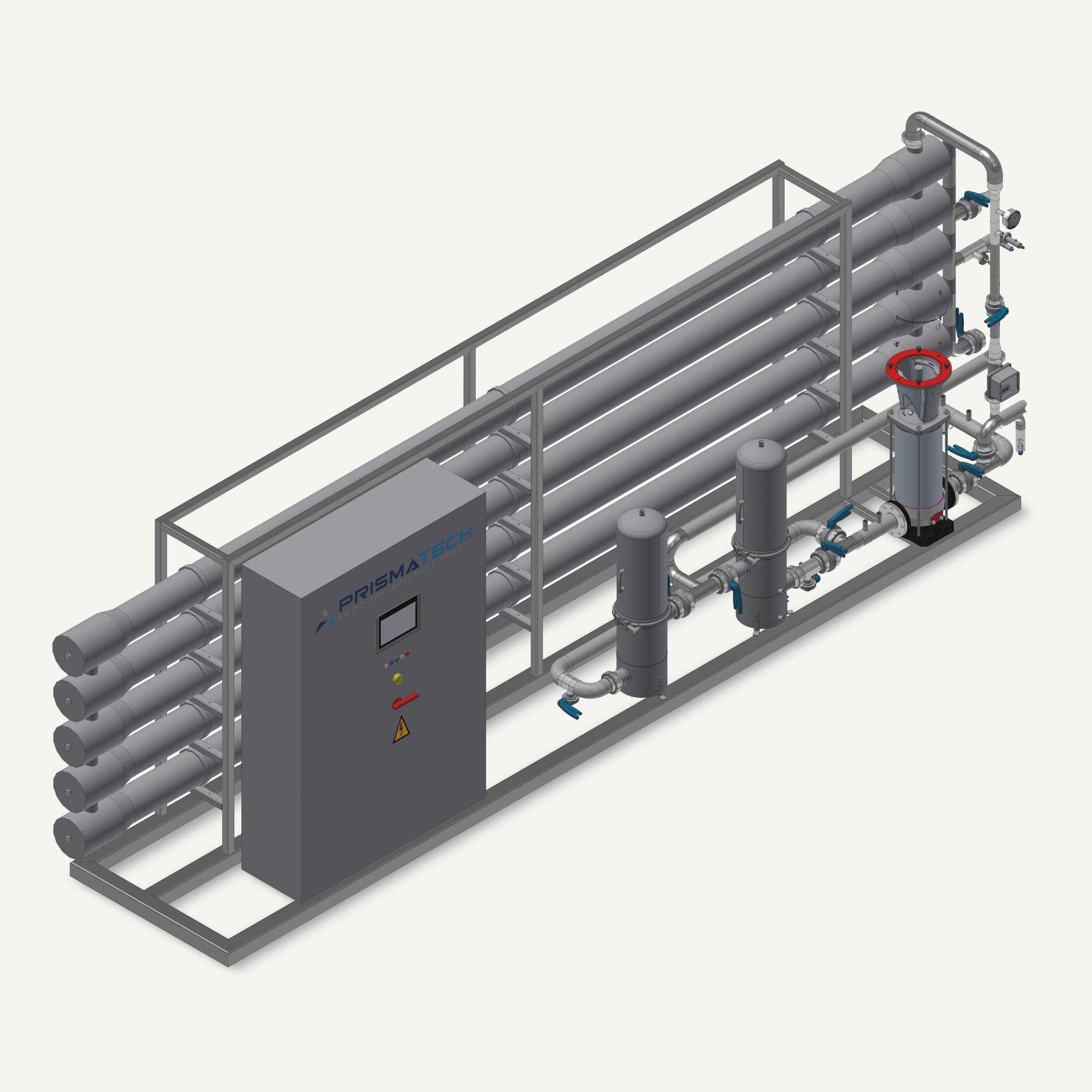

- Ozone disinfection: An ozone unit can be installed after the reverse osmosis (RO) process to eliminate any bacteria still present in the water. The ozone comes into contact with the water for a sufficient period to ensure disinfection, after which it starts its natural deterioration (ozone breakdown). The use of ozone is particularly effective in water treatment as it acts quickly against pathogens and leaves no chemical residue in the treated water, any ozone residue can be permanently removed by UV disinfection.

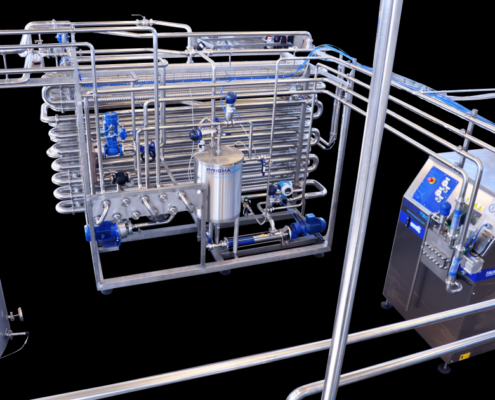

- Disinfection with UV: The use of ultraviolet light is highly recommended at the end of any water treatment line. This method is effective in destroying the bacteria present and breaking down any residual ozone. In addition, UV disinfection systems can be placed at various points in the process chain to provide an additional level of safety. UV light can eliminate pathogens without the use of chemicals, making this method environmentally friendly and safe for the treated water.

Each disinfection method has its specific role within the water treatment process, helping to ensure that the treated water is safe and suitable for its final purpose. The choice of method will depend on the requirements of the process and the characteristics of the initial water, which is why it is important to have a detailed analysis of the raw water.

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed to offer high performance and maximum reliability, PURI-TECH systems always guarantee water that is safe for human consumption as they eliminate bacteria and pathogens that can cause health problems.

In every industrial process for beverage production and water treatment, PRISMATECH ensures energy efficiency, preservation of water characteristics for a high quality end product and minimisation of water waste

- NATURAL MINERAL WATER

- SPARKLING MINERAL WATER

- FLAVOURED WATER

- COLLAGEN WATER

- FUNCTIONAL WATER

- DRINKS

- BEAUTY PRODUCTS

- CLEANING PRODUCTS

- COLD FILLING

- ULTRACLEAN FILLING

- ASEPTIC FILLING

- BRICK CARTON FILLING

- PET FILLING

- GLASS FILLING

- CAN FILLING

- 5 MC/H

- 120 MC/H

- MODULAR

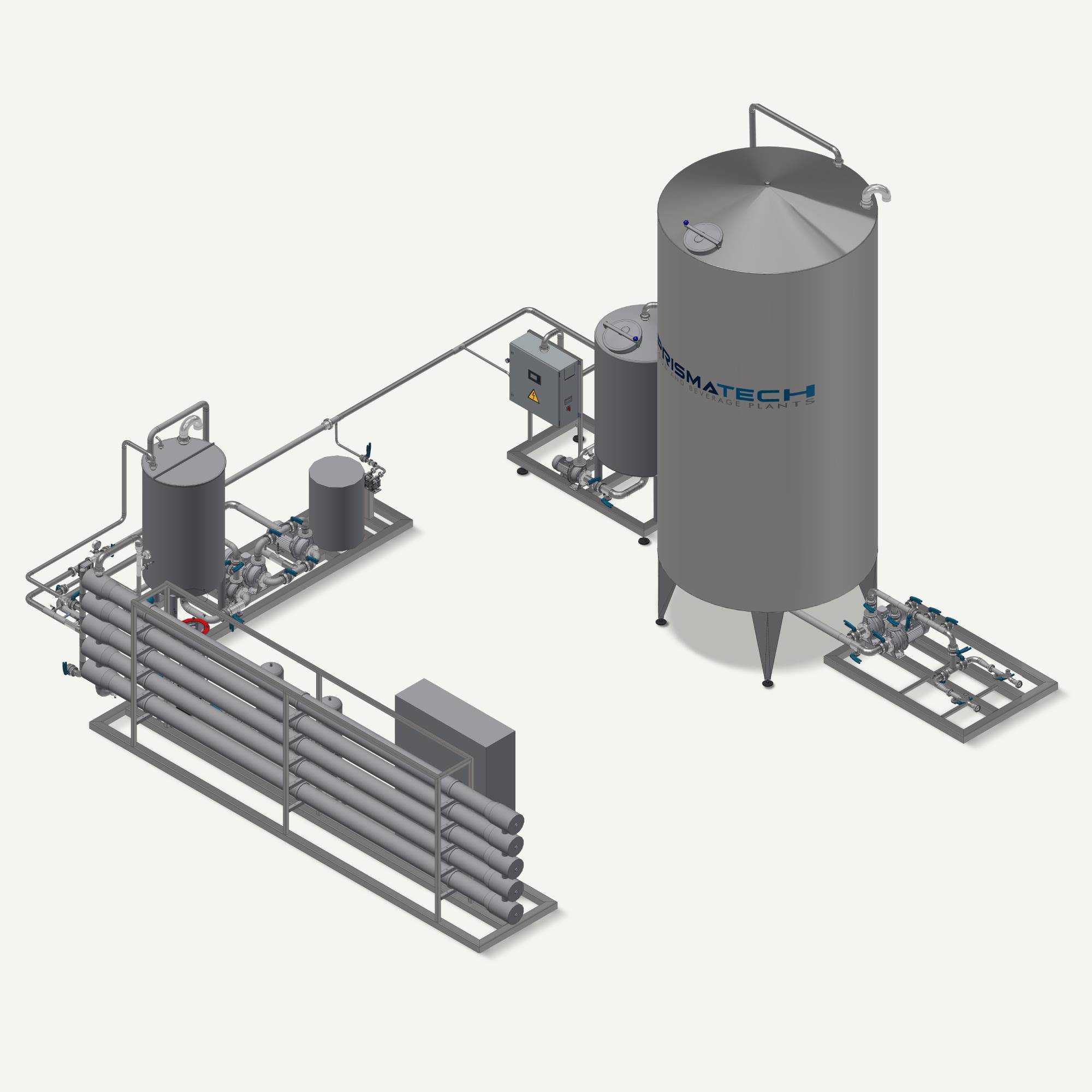

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON ADJUSTABLE FEET

- CUSTOMISED

- AUTOMATIC

- SEMI-AUTOMATIC

- MANUAL

- FLUID VELOCITY CONTROL

- CONDUCTIVITY CONTROL

- DOSAGE CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

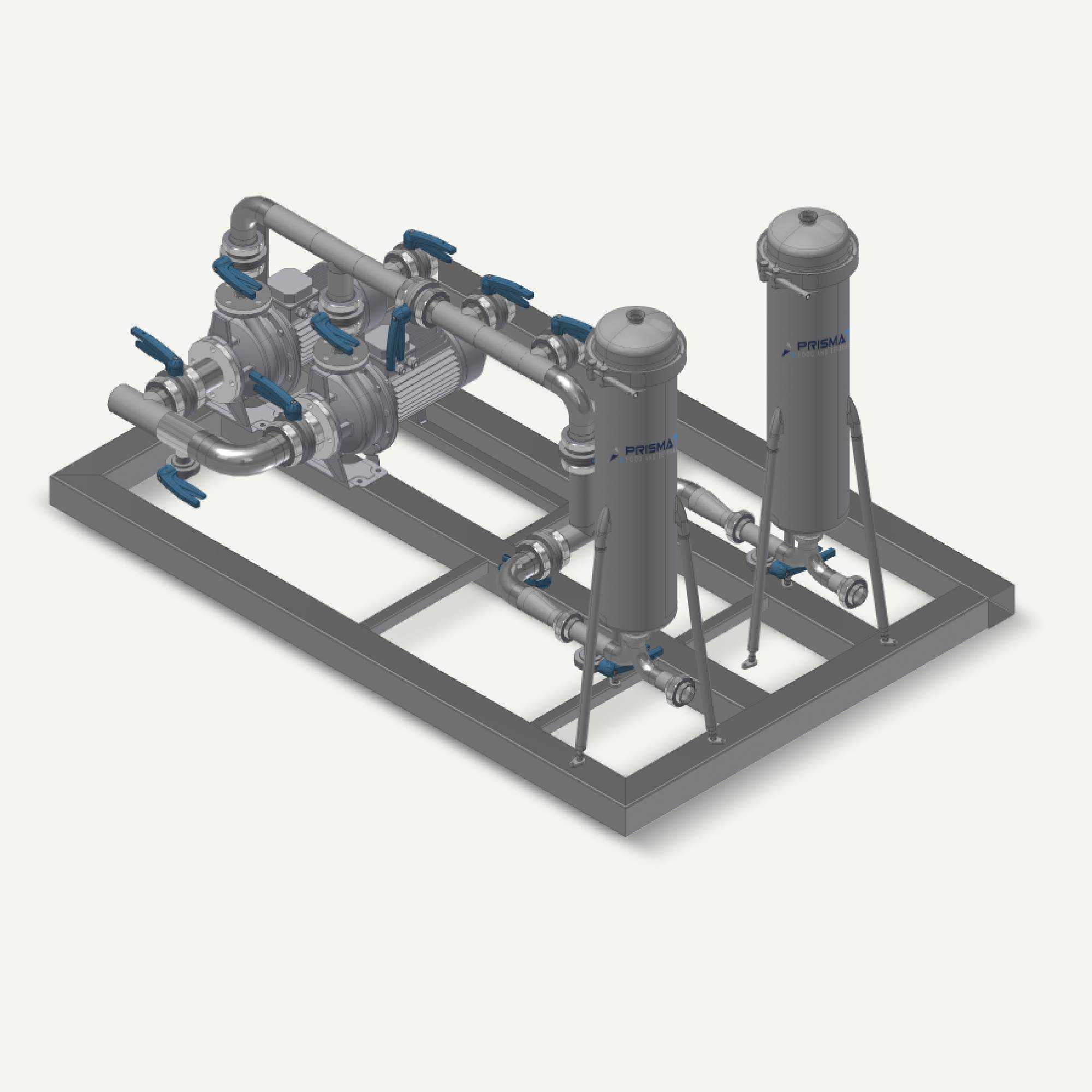

- OZONE DISINFECTION

- CHLORINATION

- UV TREATMENT

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0