MICRO-TECH MICRO-INGREDIENTS

SYSTEMS FOR DISSOLUTION AND PREPARATION OF MINOR INGREDIENTS

Micro-nutrients, or microelements, are additives commonly used to impart texture and viscosity to certain foods or beverages and to improve their shelf life, without compromising the taste and appearance of the product.

The use of micro-ingredients in fruit juice plants allows consumers to enjoy juices all year round and producers to take advantage of fresh, seasonal fruit, helping to prevent or reduce the tendency of solid separation in juice products.

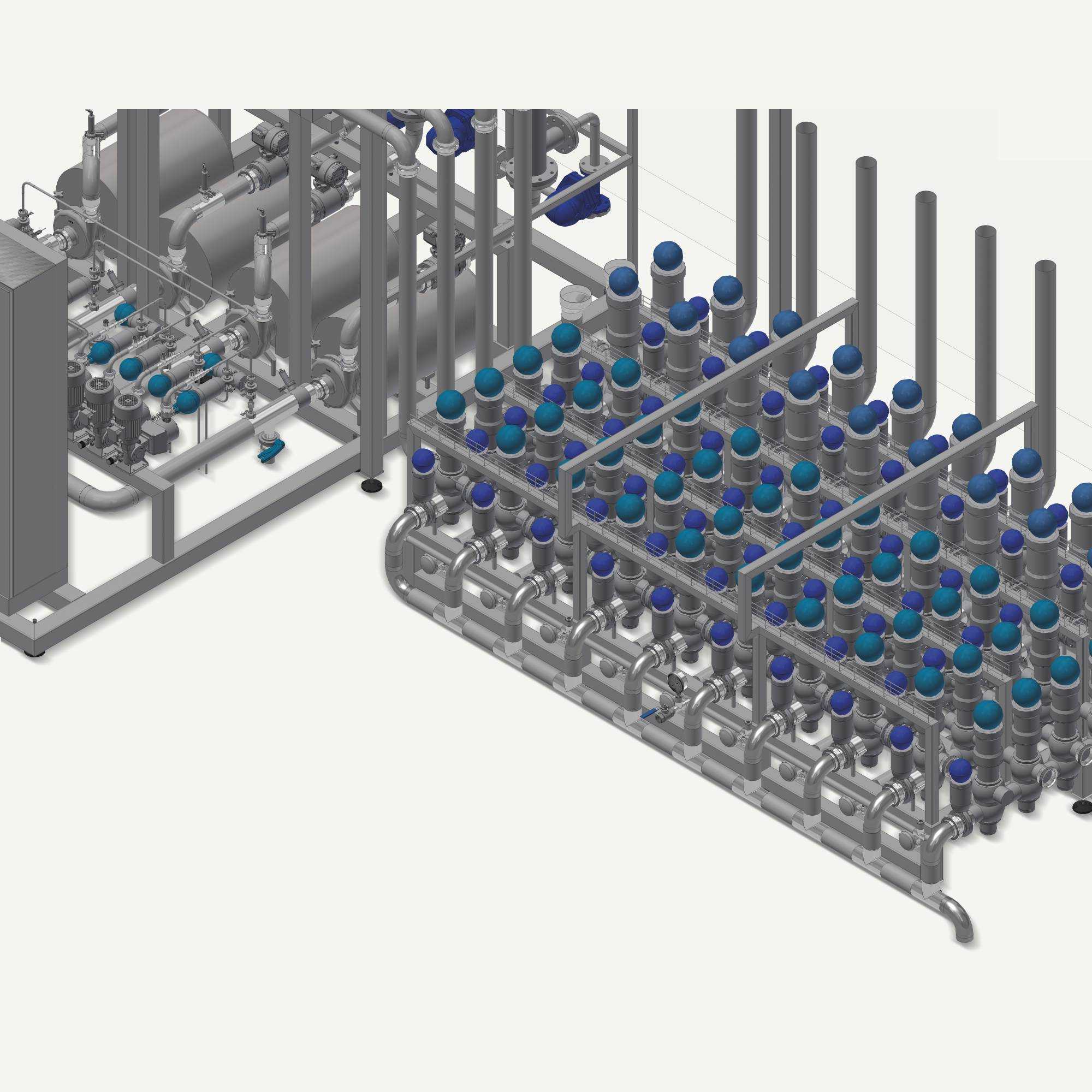

PRISMATECH minor ingredient dissolvers are available in both batch and continuous systems, depending on the required capacity.

The type of dissolution system is determined by the type of minor ingredient to be processed, which may be in a dry (powder-like) or liquid state:

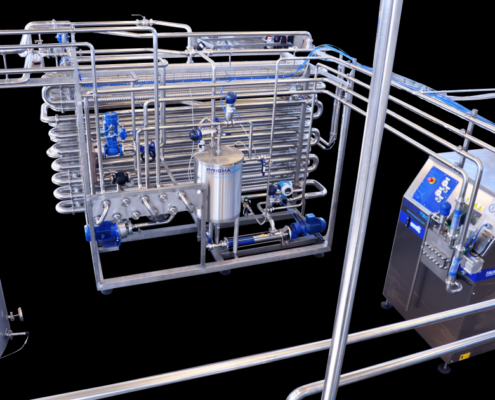

- Simple dissolution system for dissolving powders or liquids, equipped with a high-speed stirrer and suitable for additives whose dissolution takes place without heating.

- Complex dissolution system for powder or liquid dissolution, suitable for pectins with stabilising and thickening functions. These additives can work in both juices and juice concentrates to help emulsify and improve viscosity. In this case, it is equipped with an emulsifying shear mixer and a heating unit.

- Dosing system for liquid ingredients, emptying and dosing system for low and high viscosity contents, e.g. concentrates, purees, liquid additives.

- Alcohol management system for dosing the alcohol concentration for the production of alcohol-based drinks.

Once dissolved, these additives are transferred to the preparation tanks and mixed into the final drink or syrup by means of a pump.

Different levels of automation are available for dosing and transfer, including:

- Load cells for controlled dosing

- Mixproof valves for fully automatic dosing and transfer

- Mass flow meter for recipe-dependent product quantity adjustment

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed for high performance and maximum reliability, PRISMATECH Microelements are able to meet any space and process requirement, always ensuring great energy savings.

In every industrial beverage process, PRISMATECH guarantees energy efficiency, preservation of beverage characteristics for a high-quality product, and minimisation of waste.

- AISI 304

- AISI 316L

- FRUIT JUICE

- FLAVOURED WATER

- COLD TEA

- PUREE

- FLAT DRINKS

- CARBONATED DRINKS

- SYRUP

- DETERGENTS

- 150 L

- 15.000 L

- MODULAR

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON ADJUSTABLE FEET

- CUSTOMISED

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- LOAD CELLS

- HIGH-SPEED STIRRER

- COWLES STIRRER

- HIGH-SHEAR MIXER

- MASS FLOW METER

- MAGNETIC FLOWMETER

- DOSAGE CONTROL

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0