MIX-TECH PREMIX

SYSTEM FOR BEVERAGE MIXING AND CARBONATION

The MIX-TECH beverage mixer from PRISMATECH is an automatic combined system for deaeration, mixing and carbonation of soft drinks and alcoholic beverages, such as:

- Carbonated Drinks (CSD)

- Soft drinks

- Malt beverages

- Mocktails

- Alcoholic premixes (Cocktail/Alcopop)

- RTD drinks (Ready-to-drink)

- Flavoured water (sparkling and still)

- Energy drinks

- Isotonic drinks (Sports drinks)

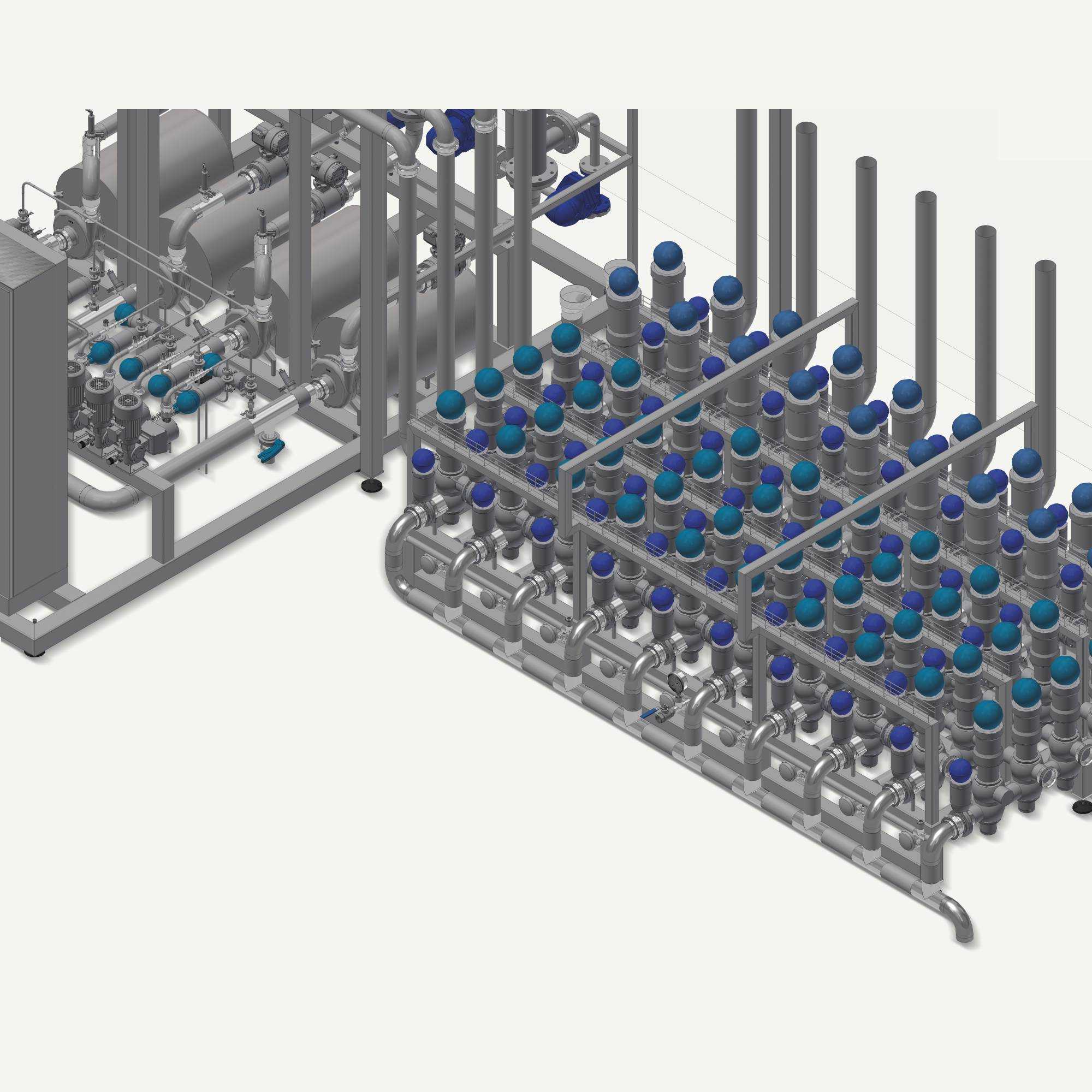

This beverage mixer is a state-of-the-art modular system:

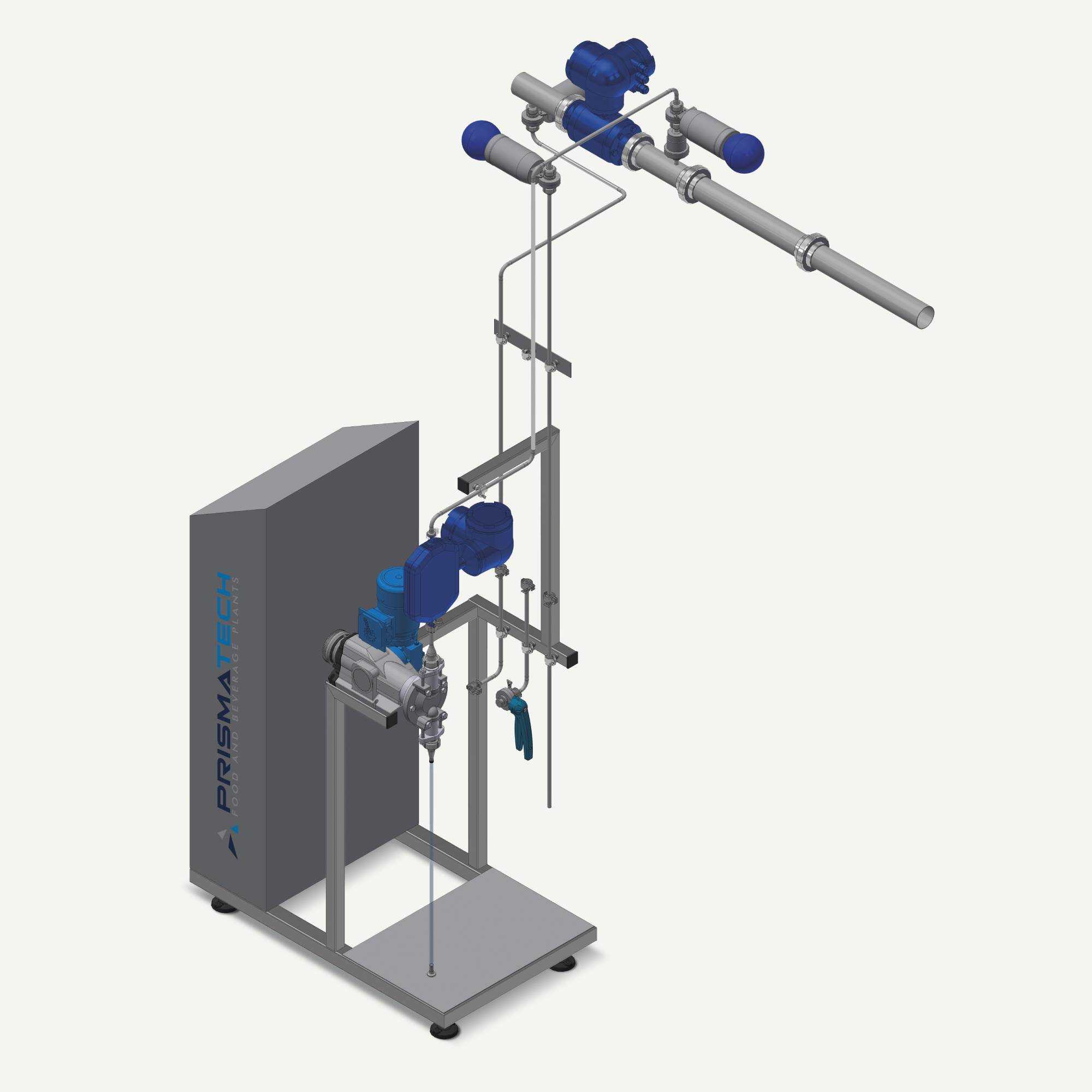

- The integration of a flavour dosing unit allows the preparation of flavoured still water and flavoured sparkling water.

- The integration of an alcohol dosing unit enables the safe preparation of alcoholic beverages.

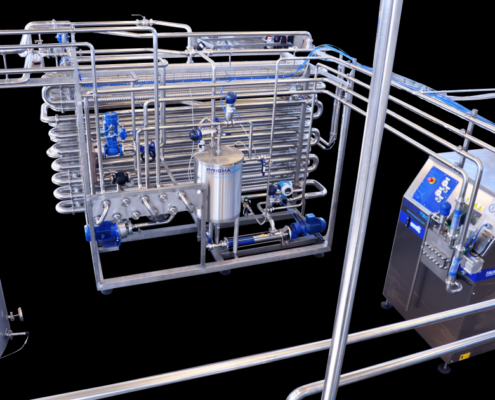

The use of a horizontal deaeration tank increases contact time and water dispersion, thus improving deaeration. The tank is also equipped with a ring of multiple nozzles for better atomisation, which allows even more oxygen to be removed and persistent carbonation to be achieved (before and after opening the product). Better deaeration can be achieved by implementing a double or triple deaeration process that aids CO2 absorption.

With the high-precision Brix and CO2 monitoring and dosing systems, a finished drink that respects the recipe parameters is achieved, thanks to the in-line control that self-adjusts any dosing errors that may have occurred during preparation in the syrup room.

The premix is complete with electronic level indicators for continuous tank level readings and better flow control and is equipped with a cooling plate exchanger that helps not only reduce the temperature of the water and syrup, allowing not only more stable carbonation, but also preventing foaming problems during the preparation and filling processes.

The state-of-the-art software enables the visualisation of trends in product production data, as well as water, syrup and CO2 consumption, for better accuracy and customer operations, who can then more accurately estimate energy and ingredient consumption in current and future productions. In addition to the PLC control panel and HMI touchscreen for automatic management of all processing steps and data, other automation upgrade options are possible:

- Brix refractometric analysis unit for accurate monitoring of sugar content in both sugar-containing soft drinks and diet drinks

- CO2 analysis unit for reading the level of carbon dioxide in carbonated soft drinks

- O2 analysis unit for reading the oxygen level in drinks

Greater compactness for simplified shipping and installation: the MIX-TECH premixer is a compact, space-saving unit that requires no disassembly for transport, so a single container is sufficient.

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed for high performance and maximum reliability, PRISMATECH Premixes meet all space and process requirements, always ensuring great energy savings.

In every industrial beverage process, PRISMATECH guarantees energy efficiency, preservation of beverage characteristics for a high-quality product, and minimisation of waste.

- AISI 304

- AISI 316L

- CARBONATED SOFT DRINKS

- ENERGY DRINKS

- FLAVOURED WATER

- HARD SELTZER

- PRE-MIXED COCKTAILS

- NON-ALCOHOLIC COCKTAILS

- ALCOHOLIC BEVERAGES

- SOFT DRINKS

- GLASS FILLING

- CAN FILLING

- PET FILLING

- 500 L/H

- 60,000 L/H

- MONOBLOCK SKID

- AUTOMATIC

- WATER DOSAGE CONTROL

- SYRUP DOSAGE CONTROL

- CO2 DOSAGE CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- DEAERATION WITH CO2,DEAERATION WITH VACUUM,DOUBLE DEAERATION,TRIPLE DEAERATION,MASS FLOW METER FOR WATER,VOLUMETRIC PREMIX,AROMA SECTION,BRIX ANALYSIS KIT,DIET ANALYSIS KIT,RESIDUAL O2 ANALYSIS KIT,CO2 ANALYSIS KIT,COOLER (PHE)

(ON REQUEST)

- MOCA 1935/2004 CE,FDA,ATEX,INDUSTRY 4.0