CLEAN-IN-PLACE CLEANING AND SANITISING

The cleaning and sanitising of plants are indispensable for maintaining the efficiency of production processes and product quality.

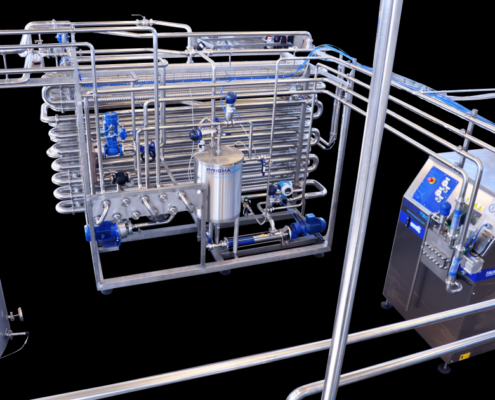

Clean-in-place (CIP) systems are systems mainly used in the food and beverage, pharmaceutical and chemical industries for cleaning and disinfecting production facilities, such as tanks, pipes, valves and other equipment, without the need to manually dismantle them. They fulfil the growing need for high standards of hygiene and cleanliness while ensuring efficiency and reducing downtime.

Thanks to continuous research into innovation and attention to industry needs, our CIP washing systems are constantly being optimised and improved to offer manufacturers high-performance solutions which make their processes more efficient, contributing to more sustainable production.

Advantages of our Cleaning-In-Place CIP systems:

Customisation

All our process machines are prepared for Cleaning-In-Place washing and each CIP system is fully customisable depending on the product to be washed and the flow rates required.

Product quality assurance

Our CIP systems are designed to eliminate contaminants or bacteria responsible for compromising quality, ensuring the excellence of the final product.

Production and energy efficiency

PRISMATECH CIP cleaning units increase the efficiency of beverage processing operations. Automated cleaning and sanitising results in significant savings in time and labour costs as well as reducing the risk of human error.

Water neutralisation

Wastewater neutralisation by CIP plants refers to the process of treating wastewater to dispose of it in accordance with local and environmental regulations. Wastewater generated during the sanitisation of machinery may contain residues of cleaning chemicals, bacteria, impurities and organic substances, making it polluting and harmful to the environment if discharged without treatment.

Cost Reduction

Our CIP systems help to reduce the costs associated with manual cleaning and downtime for equipment maintenance. Our CIPs also ensure constant equipment maintenance, reducing the risk of breakdowns and costly repairs. The recovery of washing agents, optimisation of the heating system and reuse of water in industrial washing plants also lead to further savings in operating costs.

FLEXIBILITY, EFFICIENCY AND QUALITY

Our washing systems are made of durable materials with high quality components to guarantee the highest “Made in Italy” standards. They are equipped with various automation options and control systems and can be easily integrated with any process and end-of-line in the industrial supply chain a diverse range of sectors, meeting the specific needs of different industries. Our plants are designed and optimised to offer great energy and water savings.

![[:it]Orsadrinks[:] 1 prismatech food and beverage plants case studies orsadinks anteprima](https://www.prismatech.it/wp-content/uploads/2025/12/prismatech-food-and-beverage-plants-case-studies-orsadinks-anteprima.jpg)